Walailak Frontier 15, April 2019

Nakhon Si Thammarat, a large city in the southern region, is underlain by soft compressible clay and peaty soil deposits. The chemical stabilization of soft soil deposits is commonly undertaken prior to the construction of road embankments and highways in this congested lowland area. Currently the soil-cement mixing technique by jet grouting to create a stabilized composite soil is widely adopted for soft clay stabilization. Portland cement is widely used for soil stabilization. However, its production consumes significant energy coupled with high CO2 emissions. The production of 1 ton of cement can generate approximately 1 ton of CO2. As a result, the use of alternative low carbon binders to Portland cement for soil stabilization projects has generated significant interest world-wide.

Alkali activated geopolymer binders are still at the early stages of development and can potentially produce better mechanical properties than Portland cement. Alkali activated materials are produced through the reaction of an alumino-silicate normally supplied in powder form as an industrial by-product or other inexpensive materials (such as kaolin, fly ash, bottom ash, rice husk ash and palm oil fuel ash) with an alkaline activator, which is usually a concentrated aqueous solution of alkali hydroxide, silicate, carbonate, or sulphate. The engineering properties of geopolymers that are sought for civil engineering applications include: high compressive strength, rapid controllable setting and hardening, fire resistance, various acids and salt solution resistance, high durability against wetting and drying cycles; lack of deleterious alkali–aggregate reactions and low shrinkage. Palm oil fuel ash is produced by burning the fibre, shells and empty fruit bunches of palm oil trees at 800–1000°C to create a fuel to heat steam for electricity generation purposes. Palm oil fuel ash is mainly disposed to landfills, which causes negative environmental impacts such as pollution of the air, land, and water as well as other health related problems.

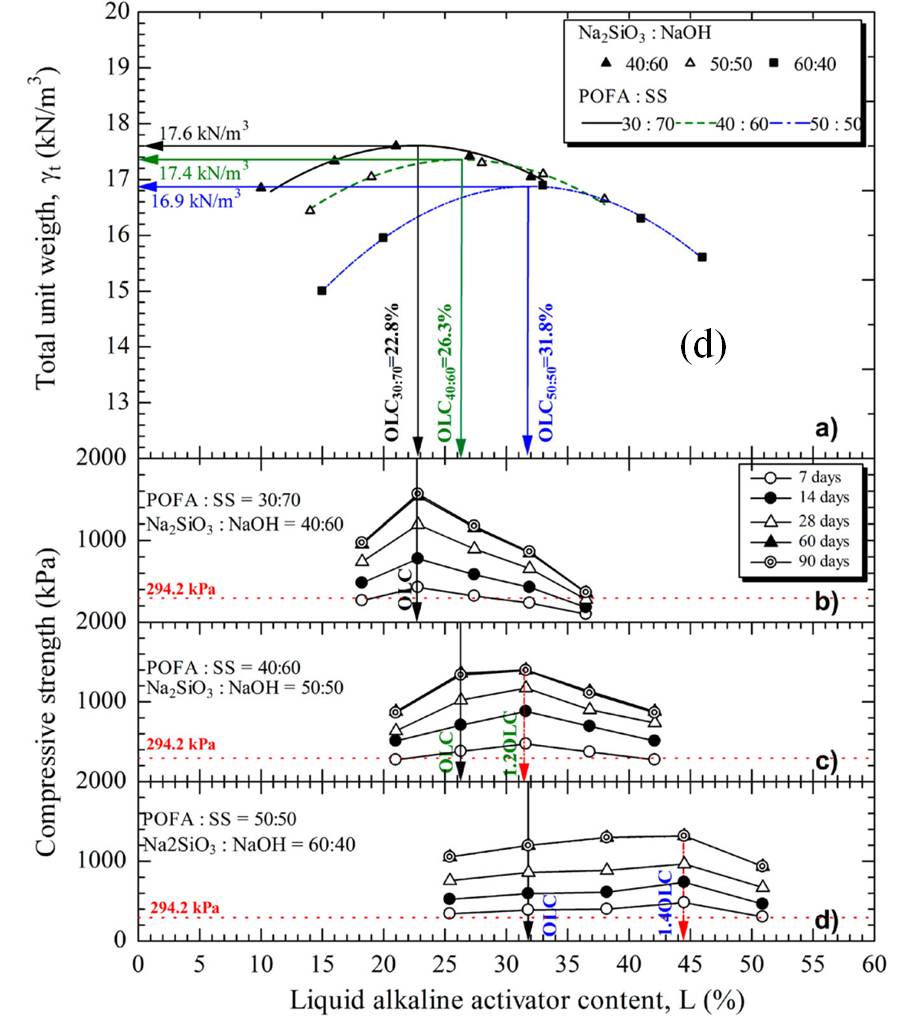

In Thailand, more than 100,000 tons of palm oil fuel ash are generated each year. Recently, Palm oil fuel ash has been mixed with other alumino-silicate materials, such as ground granulated blast furnace slag, rice husk ash, and fly ash, to generate geopolymer concretes. For geotechnical and pavement applications, fly ash, calcium carbide residue and ground granulated blast furnace slag have been used as precursors for geopolymers in soil stabilization. However, the research and application of silica-rich POFA as a precursor for the geopolymerisation of soft clay at an ambient room temperature is very limited, thus is the focus of this work. This work presents Palm oil fuel ash-soft soil geopolymer can be applied as a subgrade material in the southern region of Thailand. The 7-day strength values of the Palm oil fuel ash-soft soil geopolymers were found to meet the strength requirement of subgrade materials specified by the DOH (DH-S102/2532), Thailand.

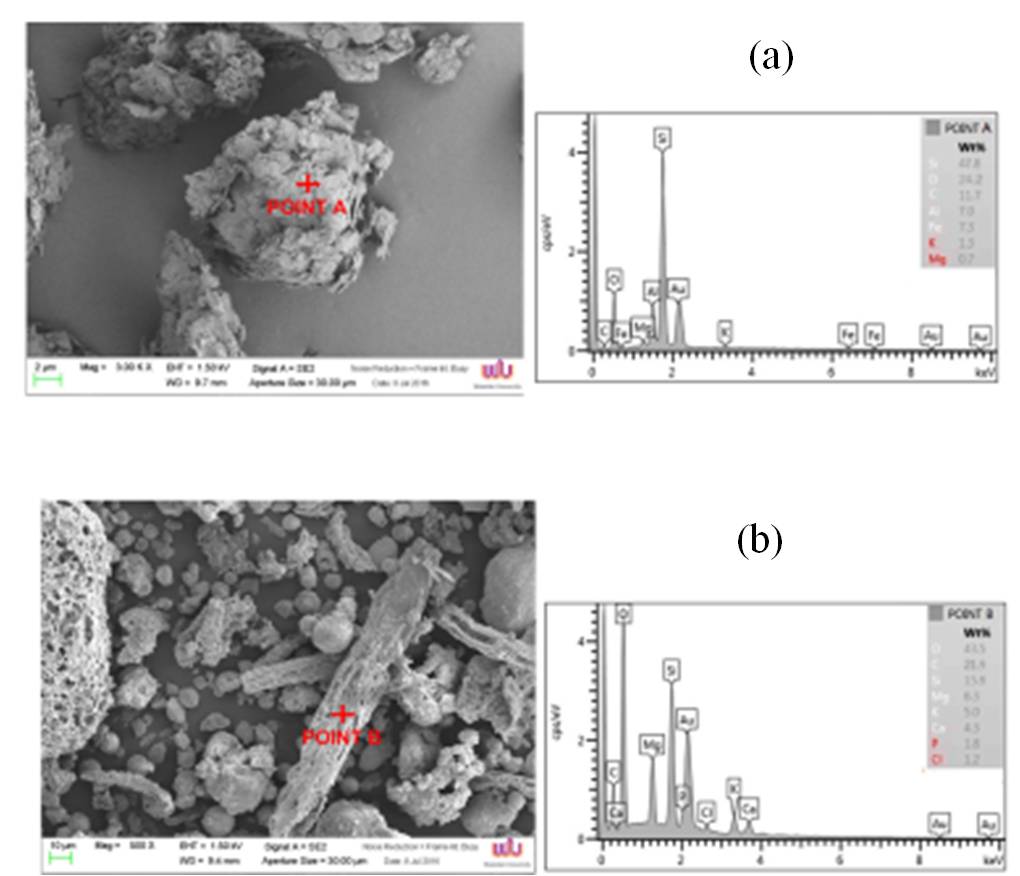

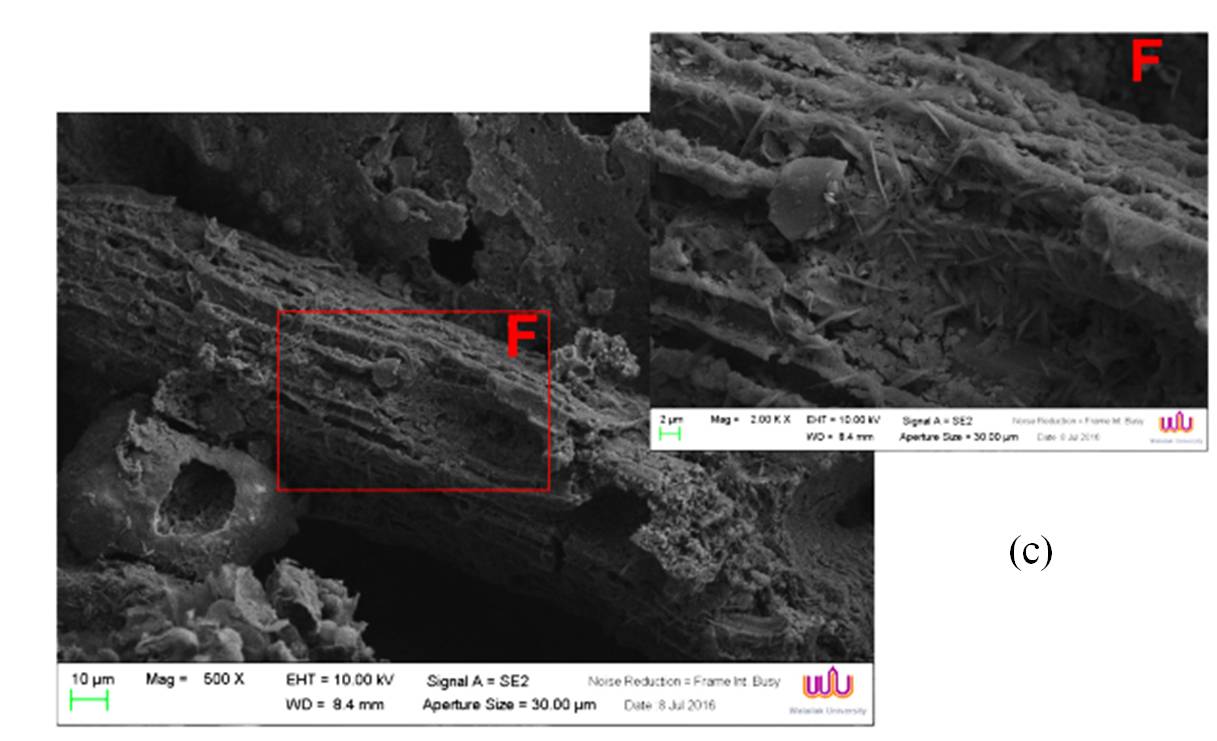

Figure. SEM/EDX photos of (a) Soft soil and (b) Palm oil fuel ash (c) Palm oil fuel ash-soft soil geopolymer and (d) Effects of liquid alkaline and Palm oil fuel ash-soft soil ratio on strength development for Palm oil fuel ash-soft soil geopolymer.

Sources:

Patimapon Sukmak, Gampanart Sukmak, Suksun Horpibulsuk, Monthian Setkit, Sippakarn Kassawat & Arul Arulrajah (2019), Palm oil fuel ash-soft soil geopolymer for subgrade applications: strength and microstructural evaluation, Road Materials and Pavement Design, 20:1, 110-131

Facebook: wufrontovation

Related Link: