This recently announced research was commissioned to solve a problem for Value Sourcing Co., Ltd who produces a well-known frozen ready meal, baked spinach with cheese, for 7-ELEVEN convenience stores under the brand REO's Deli. Although this frozen ready meal has become very popular, the producer has sought a way to overcome an uneven microwave heating problem. The success of packaging development to solve this problem has created value and market opportunities for the frozen food industry.

The package was developed by a team led by Assoc. Prof. Dr. Mudtorlep Nisoa, lecturer at Walailak University's School of Science and the head of the Center of Excellence in Plasma Science and Electromagnetic Waves. His team consisted of Mr. Apinan Plodkaew and Ms. Karaket Wattanasit from the Center of Excellence in Plasma Science and Electromagnetic Waves as well as Asst. Prof. Warasri Saengkrajang from Nakhon Si Thammarat Rajabhat University.

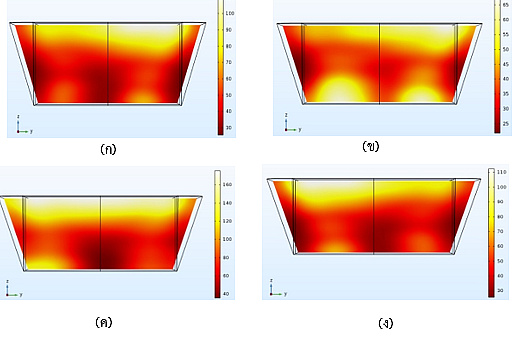

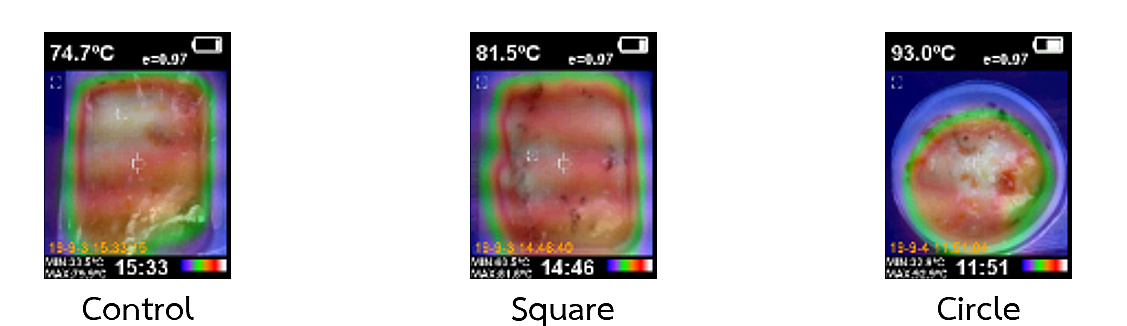

Assoc. Prof. Dr. Mudtorlep Nisoa says that the key to this research is the creation of a model to simulate microwave radiation and then experimenting with the original package to identify the cause of uneven heat distribution. The results show that the temperature in the center is much lower than the outer edge. This happens because of limited radiation wave penetration. Solutions to the uneven heat problem include reducing the thickness of baked spinach and cheese and partially closing the package with conductors (copper or aluminum foil). With these adjustments, heating is more evenly distributed, resulting in less than 10 degrees Celsius temperature difference between center and outer edge and temperatures higher than 70 degrees Celsius in the middle. Another solution is the development of a paper box covered with a thermal conductor for packaging. When used, the center temperature of the cheesy spinach is more than 50 degrees Celsius and the temperature difference is less than 10 degrees.

Mr.Chana Wasuwat, Managing Director of Value Sourcing Co., Ltd., publicly acknowledged on https://www.smethailandclub.com that the developed packaging is able to solve the indicated problems: reducing the temperature difference between the middle and the outer edge of a ready meal, resulting in a food which is heated evenly throughout. For regular microwave-safe packaging, the post says, the temperature at the outer edge may reach 84 -90 degrees Celsius, but the temperature at the center of the food is only 50 -55 degrees. For the packaging developed by Assoc. Prof. Dr. Mudtorlep Nisoa and team, the temperature difference between the outer edge and the center is less than 10 degrees Celsius. This packaging innovation solves not only Value Sourcing’s problem but also remedies a challenge for the entire frozen food industry. Mr. Chana Wasuwat added that it is more difficult to sell frozen foods because frozen foods take longer to heat than chilled foods. This new packaging will allow frozen foods for even heating and create a huge opportunity for the frozen food business. The packaging is now in late-stage testing prior to commercialization.

The packaging developed for heating frozen spinach with cheese has been registered for a petty patent. Also, Value Sourcing Co., Ltd is seeking a contract with Walailak University and the Thailand Science Research and Innovation (TSRI) to exercise its rights for production and commercial distribution for a period of 7 years.

Sources: https://www.wu.ac.th/th/news/19173

https://www.smethailandclub.com/

Rewritten from Thai by Uraiwan Angkanawisut